Expert opinion: Sustainability in the production of Qazaq Oil filling stations

“The main ways to reduce the amount of waste in production are competent design and technological development of products and the production of products in large batches", — Oleg Frantsuzov, chief technologist of VDS Company, on the experience of optimizing production waste using the Qazaq Oil filling station network as an example.

24. 05. 22

Canopy and stele frieze panels

Optimization of the design of the canopy and stele panels reduced manufacturing costs and reduced the amount of galvanized steel waste by more than 3 times.

Stele metal frame

“During the transition to mass production, we agreed to supply a beam that is equal to the height of the stele. This made it possible to eliminate 30% of of metal waste!" — Oleg Frantsuzov.

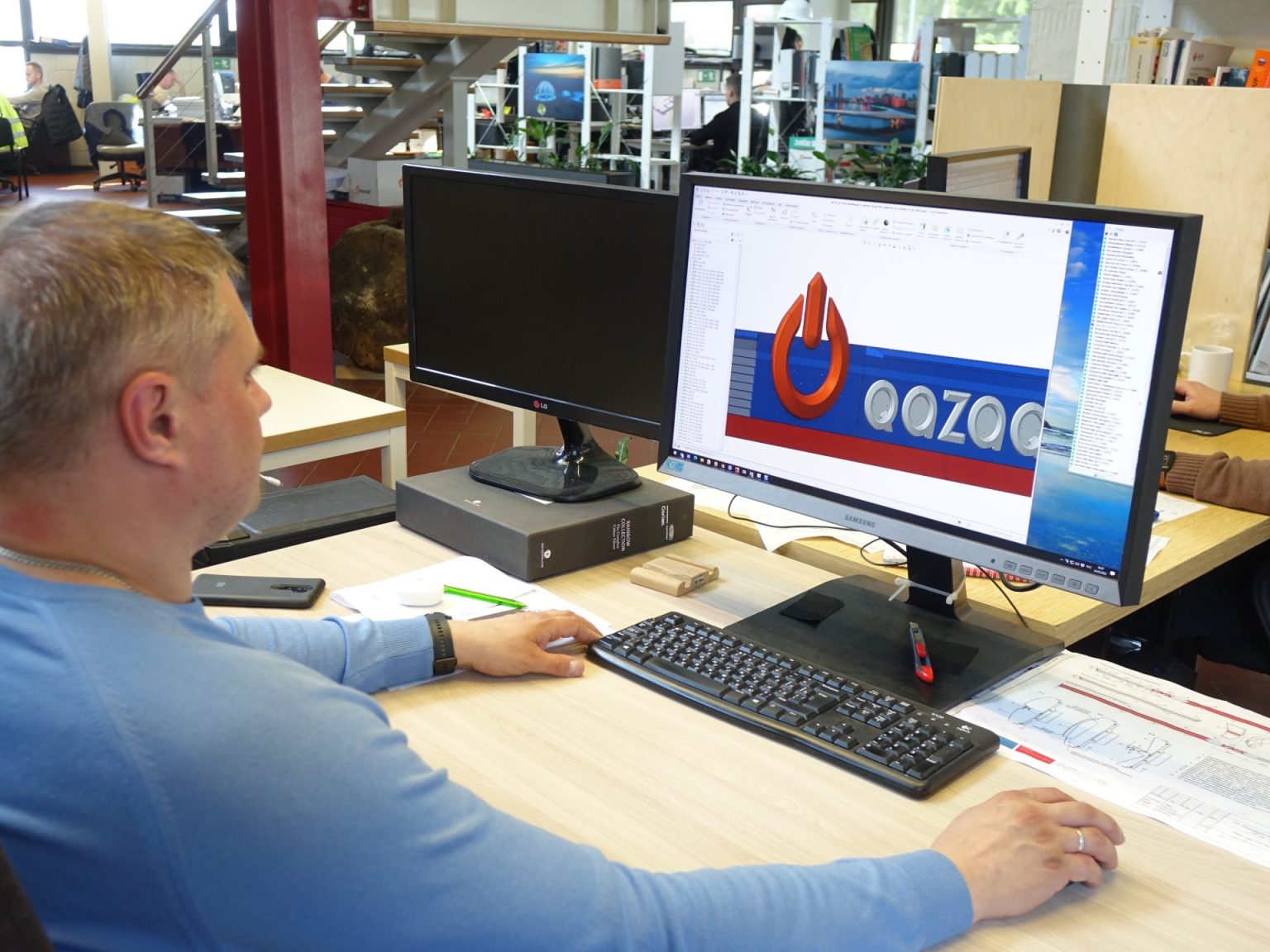

Canopy and stele sign

As a result of finalizing the design of the molded sign, the use of acrylic glass was reduced by 2 times, which made it possible to remove one extra mold from the process. Waste reduction per product was 30%.

In preparation for mass production, a development of all parts is worked out in such a way that they are optimally located on a sheet of metal with a minimum amount of waste. Competent study implies a reduction in labor costs for the manufacture of the product and the required production space.

Mass production allows you to optimize the purchased material and its consumption. As a result, we obtain a product without loss of visual and quality characteristics with minimal waste of materials during production.